Activated Sludge Process Design Pdf

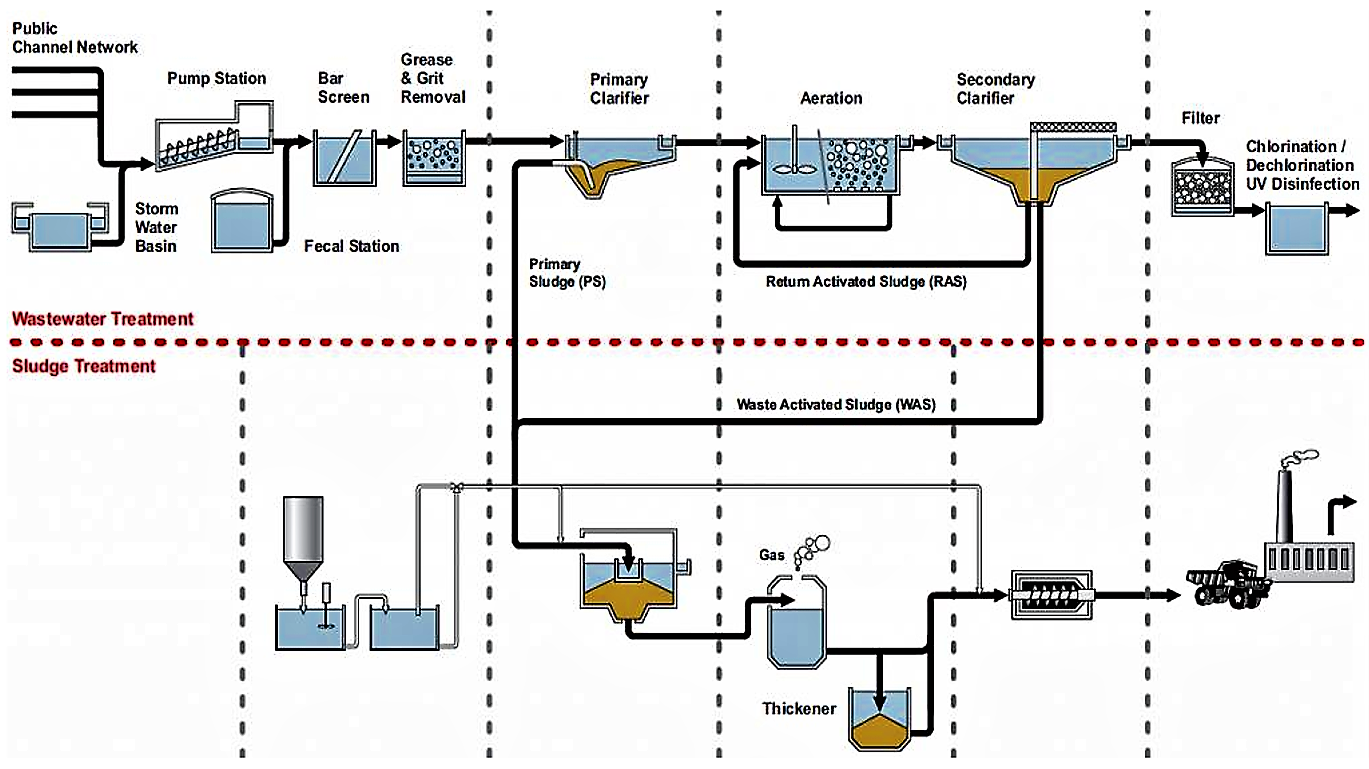

Examples of Activated Sludge Design Part 1 bCOD Removal Wastewater properties. DESIGN AND CONSTRUCTION OF SLUDGE TREATMENT FACILITIES Figure 61 Example of solids balance Conventional Activated Sludge Process In case of option a dewatering and incineration the solids balance occurs as follows.

Activated Sludge Process Design Criteria Engineering Articles

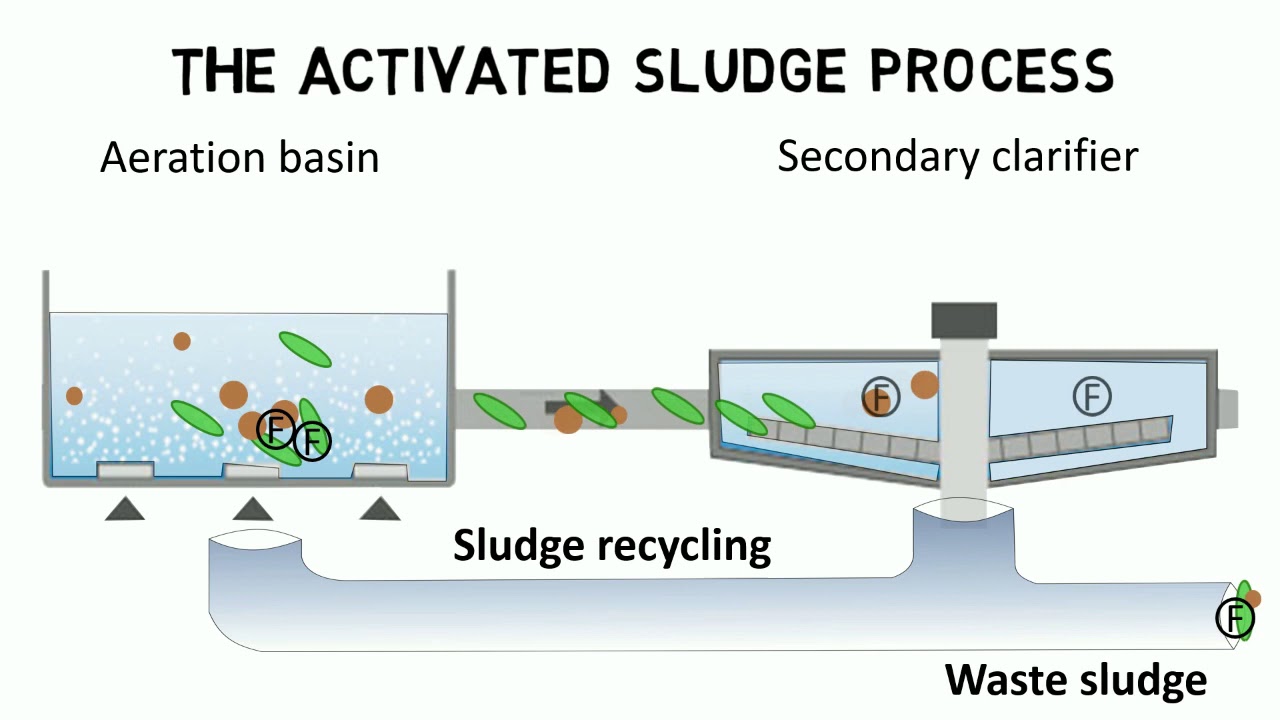

Both tanks connected through the sludge return Figure 1.

. In the activated sludge treatment process the removal of suspended solids from wastewater is usually through gravity separation in a clarifier. Up to 8 cash back Contents. General Approach - Clarifier Design - Aeration Tank Reactor Design - Appurtenance Design -.

Return Activated Sludge RAS Waste Activated Sludge WAS Q SO Q-QW S Xe QW Xr S Qr Xr S QQr S X Secondary Clarifier Completely Mixed Activated Sludge CMAS Bioreactor Design Equations Mass Balance. Tablished wastewater treatment plant design procedures. ACTIVATED SLUDGE PROCESS CONTROL.

Introduction The activated sludge process ASP is the most widely used wastewater treat-ment technology. Return activated sludge systemSV1. INCREASE CAPACITY OR DECREASE LOADING Equalize Flows Avg.

All activated sludge process is a system comprising tank bioreactor with aeration equipment and secondary settling tank. This Activated Sludge Training Manual was prepared by the Michigan Department of Environmental Quality Operator Training staff. Nitrogen and phosphorous removal in this secondary process configuration is termed biological nutrient removal BNR.

Aeration system-oxygen requirements and oxygen transfer system. It is intended to be used as an aid in the presentation of the MDEQ Activated Sludge Process Control Training Course along with numerous handouts class discussion and an abundance of slides. Download Optimization And Design Of An Oil Activated Sludge Concentration Process Book PDF.

ACTIVATED SLUDGE TANK DESIGN Mass Balance on Substrate S and cell mass X Units in mgL also called MLVSS 08 MLSS S Substrate is the same as the soluble organic matter reported as BOD 5 Assumptions. Activated sludge microbes and converted to biomass water carbon dioxide and other gases Nitrification The process through which ammonia is oxidized to nitrite and nitrate Denitrification A process by which nitrates and nitrites are converted to gaseous end products primarily nitrogen gas. Mass balance on activated sludge tank includes the secondary sedimentation tank System at steady state ie.

Dxdt 0 and dSdt 0. The paper they published in 1914 first used the term Activated Sludge. BOX 1 CLARIFIER EFFLUENT.

Be confident in your treatment plant. For loading rates of other type sludges refer to Table 52 of the EPA Process Design Manual-Sludge Treatment and Disposal. Excess activated sludge withdrawal system and subsequent treatment and disposal of waste sludge.

Download full Optimization And Design Of An Oil Activated Sludge Concentration Process books PDF EPUB Tuebl Textbook Mobi or read online Optimization And Design Of An Oil Activated Sludge Concentration Process anytime and anywhere on any device. Davyhulme Sewage Works Manchester UK first full-scale activated sludge plant. This new activated sludge process will provide nitrification and denitrification for nitrogen removal in the first phase and phosphorous removal in the second phase.

AMMONIA 1 MGL. The Conventional Activated Sludge Process is used over a wide range of wastewater flow rates from small to very large plants. The aim of this document is to standardize the design of secondary treatment based on activated sludge process.

Our books collection spans in multiple locations allowing you to get the most less latency time to. Design of activated-sludge process involves details of sizing and operation of the following main elements. Activated sludge method of wastewater treatment born.

Secondary process to achieve nutrient removal. BOX 14 CAPACITY. Aeration tank reactor-capacity and dimensions.

Advanced activated sludge study guide wisconsin department is available in our digital library an online access to it is set as public so you can get it instantly. The process consists of delivering clarified waste-water after primary settling into an. Q 22464 m3d T 12oC C.

Keywords Activated Sludge Membrane Bioreactor Wastewater Treatment Wastewater treatment Plant Design Modeling and Simulation 1. Activated Sludge Activated Sludge by Tim Hobson Activated Sludge Books available in PDF EPUB Mobi Format. 729 Kraus Process Kraus process activated sludge is characterized by use of an aeration tank to aerate a portion of the return activated sludge.

Activated Sludge Process - Process Theory - Activated Sludge Separation Problems - References Activated Sludge Treatment of Municipal Wastewater USA. The solids load from the STP to the sludge treatment section is taken as 100. Process Theory Kinetics and Sludge Quality Control.

High-purity oxygen activated sludge is characterized by the use of high-purity oxygen instead of air for aeration. Many people feel that the activated sludge process cannot be controlled and will not perform reliably. The Activated Sludge Process In1914 British researchers Edward Ardern and WT.

Example calculations and sample. 15 to 25 lbsd1000 ft. Activated-sludge process The activated-sludge process is an aerobic continuous-flow system containing a mass of activated micro-organisms that are capable of stabilizing organic matter.

Where Q Qw influent flow and waste flow respectively m 3d V volume of aeration basin m3. The new activated sludge process would include in. The activated sludge excess biomass or cell mass removed from the secondary treatment process.

Each box will either request more data or identify the issue. View Activated Sludge Design Problempdf from ENVE 376 at University of Waterloo. Used for design unless other acceptable data are submitted.

The standard design includes the biological reactor and secondary clarifier. Download Activated Sludge books From the books introduction. For most treatment plants this will be a portion of the Return Activated Sludge RAS flow stream.

Treatment a general description of the activated sludge process information about several variations of the activated sludge process a discussion of design calculations for an activated sludge aeration tank and a discussion of activated sludge operational calculations. Table 12-2 Solids Loading Rate Type of Sludge lbdaysq ft Primary 20-30 Activated sludge 5-6 Trickling filter 8-10. This is not an introductory text about activated sludgeIn this book we discuss.

The flow diagram and general description is that given above in the Activated Sludge Background section. Lockett added the concept of recycling sludge and patented the process. Assuming that the plant is adequately designed properly maintained and operated the activated sludge process can and does produce an excellent effluent.

The aeration tank in a conventional activated sludge process is typically designed with a long narrow.

Activated Sludge Process And Ifas Design Rules Guideline Youtube

Activated Sludge Three Steps To Improve Your Process Efficiency

Activated Sludge Sswm Find Tools For Sustainable Sanitation And Water Management

Activated Sludge Process Iwa Publishing

Facts At Your Fingertips Activated Sludge Process Chemical Engineering Page 1

0 Response to "Activated Sludge Process Design Pdf"

Post a Comment